| Model() | Current(A) | Motor Power (kW) | Inductance(mH) | Loss(W) | Weight(kg) |

|---|---|---|---|---|---|

| ERM 400/8/4 | 8 | 4 | 1.75 | 32.4 | 1.4 |

| ERM 400/10/5 | 10 | 5 | 1.44 | 38.4 | 1.4 |

| ERM 400/12/5.5 | 12 | 5.5 | 1.15 | 44.1 | 1.4 |

| ERM 400/16/7.5 | 16 | 7.5 | 0.92 | 50.4 | 1.5 |

| ERM 400/20/10 | 20 | 10 | 0.74 | 51.3 | 1.5 |

| ERM 400/24/11 | 24 | 11 | 0.59 | 56.49 | 2.8 |

| ERM 400/30/15 | 30 | 15 | 0.45 | 58.8 | 2.9 |

| ERM 400/37/18.5 | 37 | 18.5 | 0.48 | 68.1 | 4.3 |

| ERM 400/50/22 | 50 | 22 | 0.3 | 95.4 | 4.9 |

| ERM 400/60/30 | 60 | 30 | 0.24 | 81.9 | 6.4 |

| ERM 400/75/37 | 75 | 37 | 0.2 | 90.03 | 7.8 |

| ERM 400/90/45 | 90 | 45 | 0.16 | 100.5 | 9.1 |

| ERM 400/110/55 | 110 | 55 | 0.13 | 141.9 | 10.9 |

| ERM 400/120/60 | 120 | 60 | 0.12 | 142.2 | 11.0 |

| ERM 400/150/75 | 150 | 75 | 0.09 | 189 | 13.4 |

| ERM 400/180/90 | 180 | 90 | 0.08 | 190.2 | 16.7 |

| ERM 400/200/100 | 200 | 100 | 0.075 | 197.4 | 18.9 |

| ERM 400/250/110 | 250 | 110 | 0.05 | 212.4 | 19.4 |

| ERM 400/300/132 | 300 | 132 | 0.046 | 256.2 | 29.2 |

| ERM 400/350/160 | 350 | 160 | 0.042 | 267 | 29.5 |

| ERM 400/400/200 | 400 | 200 | 0.037 | 286.2 | 33.4 |

| ERM 400/500/250 | 500 | 250 | 0.029 | 421.8 | 42.0 |

| ERM 400/600/300 | 600 | 300 | 0.023 | 431.7 | 54.1 |

| ERM 400/700/315 | 700 | 315 | 0.021 | 434.7 | 54.3 |

| ERM 400/800/400 | 800 | 400 | 0.018 | 442.8 | 54.7 |

| ERM 400/900/450 | 900 | 450 | 0.016 | 450.3 | 56.3 |

| ERM 400/1000/500 | 1000 | 500 | 0.014 | 477.9 | 57.0 |

| ERM 400/1200/600 | 1200 | 600 | 0.011 | 675 | 73.0 |

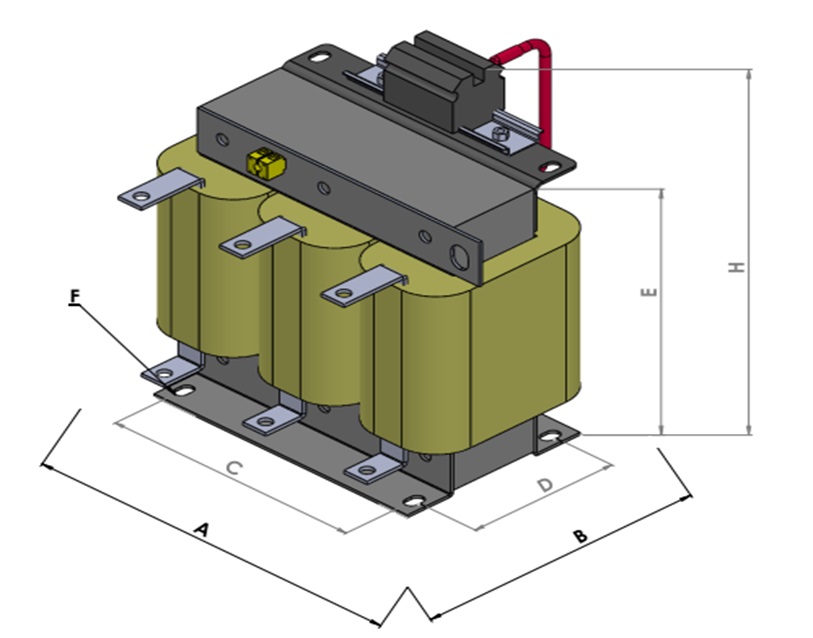

| Model() | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | H(mm) | F(mm) |

|---|---|---|---|---|---|---|---|

| ERM 400/8/4 | 120 | 75 | 90 | 53 | 5X10 | ||

| ERM 400/10/5 | 120 | 75 | 90 | 53 | 5X10 | ||

| ERM 400/12/5.5 | 120 | 75 | 90 | 53 | 5X10 | ||

| ERM 400/16/7.5 | 120 | 75 | 90 | 53 | 5X10 | ||

| ERM 400/20/10 | 120 | 85 | 90 | 63 | 5X10 | ||

| ERM 400/24/11 | 150 | 80 | 110 | 60 | 5X10 | ||

| ERM 400/30/15 | 150 | 80 | 110 | 60 | 5X10 | ||

| ERM 400/37/18.5 | 150 | 95 | 110 | 75 | 5X10 | ||

| ERM 400/50/22 | 180 | 91 | 135 | 71 | 5X10 | ||

| ERM 400/60/30 | 180 | 101 | 135 | 81 | 5X10 | ||

| ERM 400/75/37 | 180 | 161 | 135 | 91 | 155 | 5X10 | |

| ERM 400/90/45 | 180 | 170 | 135 | 100 | 155 | 5X10 | |

| ERM 400/110/55 | 240 | 158 | 185 | 83 | 205 | 10X15 | |

| ERM 400/120/60 | 240 | 158 | 185 | 83 | 205 | 10X15 | |

| ERM 400/150/75 | 240 | 168 | 185 | 93 | 205 | 10X15 | |

| ERM 400/180/90 | 240 | 178 | 185 | 103 | 205 | 10X15 | |

| ERM 400/200/100 | 264 | 192 | 200 | 110 | 243 | 10X15 | |

| ERM 400/250/110 | 264 | 192 | 200 | 110 | 243 | 10X15 | |

| ERM 400/300/132 | 300 | 202 | 224 | 120 | 255 | 10X15 | |

| ERM 400/350/160 | 300 | 202 | 224 | 120 | 255 | 10X15 | |

| ERM 400/400/200 | 300 | 214 | 224 | 132 | 255 | 10X15 | |

| ERM 400/500/250 | 360 | 220 | 265 | 130 | 305 | 10X15 | |

| ERM 400/600/300 | 360 | 270 | 265 | 160 | 305 | 10X15 | |

| ERM 400/700/315 | 360 | 270 | 265 | 160 | 305 | 10X15 | |

| ERM 400/800/400 | 360 | 270 | 265 | 160 | 305 | 10X15 | |

| ERM 400/900/450 | 360 | 270 | 265 | 160 | 305 | 10x15 | |

| ERM 400/1000/500 | 360 | 270 | 265 | 160 | 395 | 10X15 | |

| ERM 400/1200/600 | 420 | 275 | 315 | 165 | 425 | 15X21 |